|

|

|||||||||||

|

Taken

from the 7. International Conference of oriental carpets at

Hamburg/Berlin |

|||||||||||

|

|

|||||||||||

|

Dyeing is based on complex interactions between natural polymers, as for example wool or silk, and colour-specific dyestuffs of the anthraquinone, flavone or indigo series.

On the left side: Red and violet colour shades from madder (Rubia tinctorum) and blue and black colour shades from indigo in combination with madder on wool.

On the right below: Natural dyeing on silk with Rhamnus petiolaris (yellow and green). Red, brown and violet dyeing on silk with cochinille.

In recent years, modern analytical techniques have made it possible

to examine and document the chemistry of natural deystuffs in detail.

This is also substantiated by Schweppes book published in 1993. In

contrast of this, the biochemical reactions in hair structures before

and during the dyeing process are still more or less unclear. The

knowledge of these processes is, however, of fundamental importance if

we are to understand the mechanics of natural dyeing, since neither

farmers nor nomads of the oriental region had access to complicated

dyeing processes. Dyeing techniques applied by farmers and nomads are

based on experience handed down through the generations. |

|||||||||||

|

It is the simplicity of the dyeing process wich results in the wellknown reproducibility and efficiencey. Organic-chemical considerations, which are laid down in recent specialist literature in the form of innumerable dye formulae and mixtures, are of no relevance to the traditional natural dyeing process in Anatolia. This aspect of carpet manufacturing has always been neglected in oriental carpet research, which is proven by the very low number of quotable sources. Expeditions made by V.G.Moschkova between 1929 to 1945 to the carpet-making peoples in Central Asia document a multitude of old dyeing techniques being applied in these regions. Amongst other things, the following procedure was described: "They cooked millet flour in water, added a handful of alum, let the solution ferment for five days and then immersed the wool yarn in this solution for a period of ten days. It was only then that madder-dyeing was started." These references culled from the literature were to give birth to a methodical concept, which was designed to answer the following questions:

|

|||||||||||

|

|||||||||||

|

Fermentation is commonly understood to comprise those biochemical

processes which are initiated by microorganisms and which serve in

particular to prepare and preserve food. |

|||||||||||

|

|||||||||||

|

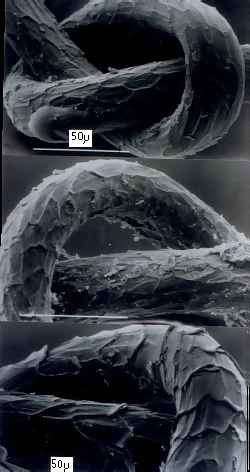

The scanning electron micrograph shows the outer hair structure to be

an even pattern of overlapping scales. Sheeps' wool comprises two ore

three layers of scales. For mordant salts and dyestuffs this outer layer

represents the first barrier on their way interior of the hair. The effect

of the Geotrichum yeast spores on the hair structure is now apparent. The

scale layers of the wool hair exfoliated to a clearly visible extent

proportionate to the immersion time of the wool yarns in the fermentation

solution. This procedure is characterised by high enzyme activity of the

Geotrichum, which results in a decomposition of fatty substances between

the scale layers. The diffusion of mordant salts and dyestuffs into the

inner hair cortex is considerably faciliated by this.

|

||||||||||

|

The properties of the wool yarn are not changed by the fermentation process described, whereas the binding capability of the natural dyestuff to the wool fibre is coniderably enhanced. This effect can be proved by means of an endurance test under direct sunlight. The picture on the right shows yellow dyeing on wool with Rhamnus petiolaris proved by a one year endurance test under direct sunlight in Istanbul 1984.

|

|||||||||||

The

photograph on the left shows the section of a 0.04 mm thick,

fermented wool hair viewed through a scanning electron microscope at

5000-fold magnification after fixing by means of osmium acid and

contrasting by means of heavy metal salts. In the left half of the

photgraph, the cuticula-exfoliation from the hair cortex can be seen -

marked by arrows. This can be ascribed to the above mentioned effects of

fermentation. The hair cortex itself is noticeably divided into two

sections: a darker section, the keratin fibres are systematically ordered

in the form of bundles, whereas in the lower section, the fibres are

arranged more randomly. The spaces between the fibres, which represent the

cell interstices in the growing hair, are filled by a matrix. The

photograph on the left shows the section of a 0.04 mm thick,

fermented wool hair viewed through a scanning electron microscope at

5000-fold magnification after fixing by means of osmium acid and

contrasting by means of heavy metal salts. In the left half of the

photgraph, the cuticula-exfoliation from the hair cortex can be seen -

marked by arrows. This can be ascribed to the above mentioned effects of

fermentation. The hair cortex itself is noticeably divided into two

sections: a darker section, the keratin fibres are systematically ordered

in the form of bundles, whereas in the lower section, the fibres are

arranged more randomly. The spaces between the fibres, which represent the

cell interstices in the growing hair, are filled by a matrix.

During the preparation process for electronmicroscopic examination, it is the matrix of the fermented wool hair (left side) which is coloured in intense black. This phenonemon can be traced back to an increased metal ion concentration. The results suggest that with the fermented wool hair, mordants can more easily penetrate into the interior of the hair, this being made possible by the exfoliation of the outer scale layers. Neither the wool fibres nor the matrix of the wool hair is structurally changed by this fermentation process. |

|||||||||||

|

|||||||||||

Technological procedures leave traces on material processed. |

|||||||||||

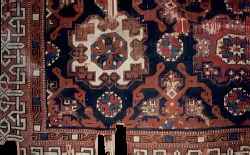

A systematic series of tests carried out on notted carpets and flatweaves from the most important Anatolian manufacturing regions finally resulted in a significant overall survey of traditional dyeing procedures. The picture on the right shows a large pattern Holbein-Carpet, 16th century (Türk ve Islam Eser Müzesi Istanbul) |

|||||||||||

The scanning electron micrographs taken of dyed wool hair from Ushak carpets in Berlin museum of Islamic Art showed a high degree of conformity regarding the exfoliation of the outer scale layer. The picture on the left shows a small pattern Holbein-Carpet, 16th century (Türk ve Islam Eser Müzesi Istanbul). |

|||||||||||

|

|||||||||||

|

In contrast to this, wool samples taken from the warp of the same carpets showed typical characteristics in non-fermented wool, i.e. closed scale layers. Exfoliation caused by fermentation was also detected in carpets from other manufacturing region. For example wool samples taken from a 16th century Aksaray carpet also showed a typical fermentation effect.

|

|||||||||||

|

|

||||||||||

|

Konya bagface

|

Yüncü flatweave

|

||||||||||

|

|||||||||||

|

Village carpet, Konya region, 19th century. |

||||||||||

The verification of findings obtained so far of sections of red-dyed pile wool from a 17th century Ushak carpet and a 19th century village carpet from the Konya region showed an increased contrast in the matrix in both cases as was already proved with fermentated wools. |

|||||||||||

|

|

|||||||||||

|

Summary Scanning microscope stdies carried out on wool hair from Anatolian carpets and flatweaves dating from the 16th to the 19th century documented a highly significant conformity in the hair structure, which can only be achieved by fermentation. Thus, this technological concept is directly connected with a dyeing procedure as discribed by Moshkova for the carpet manufacturing Turkic peoples of Central Asia. They are not the result of a convergent development but rather document the migration of traditional arts and crafts to another cultural area. In addition to this, the expedition reports by V.G. Moshkova furnish valuable information on the procedure during the actual dyeing process. Several sections of her reports refer to so-called cold dyeing technique. This procedure suggests an economic practice enabling the user to do without percious energy sources. However, the handling of such processes implies acid-stable dye baths, which prevent the wool yarn from rotting and guarantee good dyeing results.

The striking success of colddyeing can be most effectively demonstrated in the production of purple-coloured wool yarns. In order to be able to achieve purple colour shades it is of particular importance that the mordant and the dye bath temperature does not exceed 40°C. Following a pre-mordant bath of 2 to 10% concentration of green iron sulphate the yarns are placed in suspension of madder, wheat bran and sourdough. After aproximatiliy 5 to 6 days at an ambient temperature of 30°C the fermentation process is terminated. The wools, which are now medium to dark brown, are further treated in a solution of potash for 2 days at the same ambient temperature, thus producing the colour purple.

The success of dyeing process strongly depends on the temperature,

since the purple-specific dyestuff Pseudopurpurin is converted in Purpurin

at the boiling point, which then makes a clear purple impossible. |

|||||||||||

In a modified form, the cold dyeing process can also be used for the

manufacture of black-dyed wool yarns. The process is as for purple dyeing

using indigo pre-dyed wool yarns to achieve blackish-blue to deep black.

This method would have helped to eliminate the tiresome problem of

corrosive wool destruction. In former times, manufacturers of carpets and

flatweaves were familiar with this phenomenon, which is manifested in the

small number of products with a black background. |

|||||||||||

The picture on the right shows the black ground reconstruction of the red ground Kirsehir-Carpet from the Victoria and Albert Museum/London. |

|||||||||||

The manufacture of a large sized Ushak carpet required, for example 20 to 25 kilograms of red-dyed wool yarns. In order to be able to achieve satisfying dyeing results, an equal quantity of madder and an 800-litre dyeing vat had to be used. In a large scale trial it was found that it was possible to dye another batch in the same dye bath. Adding plants giving yellow dyes to the same dye bath than resulted in orange and yellow colours, whereas wool yarns pre-dyed with indigo turned a shade of green. The overall outcome with this economical concept is a saving in the dye bath of more than 3000 litres. |

|||||||||||